Special HDPE Anti-seepage Membrane for Environmental Protection Engineering

HDPE geomembrane is produced by three-layer co-blowing process or calendering process. It is an effective waterproof barrier engineering material.

1. Excellent anti-penetration performance, waterproof, anti-seepage and isolation

2.High chemical corrosion resistance

3. Better impact resistance and wear resistance

HDPE geomembrane is a geotechnical material made of high-density polyethylene.

Material: HDPE

Thickness: 0.2-3mm

Width: 1-8m

Length: according to customer needs

Features:

1. HDPE geomembrane has suitable chemical steadiness and can face up to the corrosion of robust acids, alkali and oil, and is a proper anti-corrosion material;

2. HDPE geomembrane has excessive tensile strength, which allows it to meet the desires of high-standard engineering projects;

3. HDPE geomembrane has sturdy weather resistance and anti-aging performance, and can be used uncovered for a lengthy time whilst retaining its authentic performance;

4. The typical overall performance of HDPE geomembrane. HDPE geomembrane has sturdy tensile power and elongation at break, which permits HDPE geomembrane to be used in more than a few harsh geological and climatic conditions. Adaptable to uneven geological agreement and robust stress resistance!

Application:

1. HDPE geomembrane is appropriate for environmental safety and sanitation: such as landfills, sewage cure plants, electricity plant regulating pools, industrial and clinic stable wastes, etc.

2. HDPE geomembrane is appropriate for water conservancy projects: such as anti-seepage, plugging, and reinforcement of rivers, lakes, reservoirs, and dams, anti-seepage of water channels, vertical core walls, slope protection, etc.

3. HDPE geomembrane is used in municipal projects: subways, underground engineering initiatives of buildings, planting roofs, roof gardens, and sewage pipe anti-seepage.

4. HDPE geomembrane is appropriate for aquaculture industry: intensive and manufacturing unit farming ponds, fish ponds, lining of shrimp ponds, sea cucumber circle slope protection, etc.

5. Polyethylene anti-seepage membrane is appropriate for gardens: synthetic lakes, rivers, reservoirs, pond bottoms of golf courses, slope protection, inexperienced lawns, etc.

Specifications:

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||||

Spec Properties | Test | GMS0.2 | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 | GMS3.0 |

Thickness | D5199 | 0.2mm | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm |

Density (≥ g/cc) | D1505 | 0.94 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.94 |

Tensile Properties | D6693 Type IV | 3 kN/m | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% | |

Tear Resistance (≥) | D 1004 | 25N | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N | 374 N |

Puncture Resistance(≥) | D 4833 | 64N | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N | 960 N |

Stress Crack Resistance (≥) | D 5397 | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packaging:

Stock:

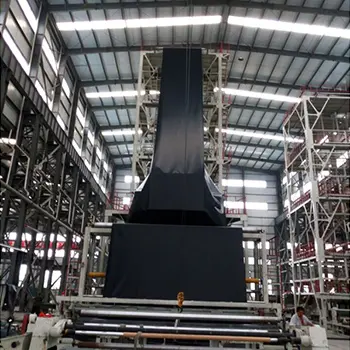

Factory: