Protective High Quality PP Geotextile

PP non-woven fabric is made of polypropylene fibers through processes such as hot melting, spraying, and high-speed air flow to form a network structure, and then undergoes appropriate heat setting, compaction and other processing processes.

1. Has high tensile strength and good anti-penetration performance

2. Can effectively enhance the stability and bearing capacity of soil

3. Excellent backflow resistance

4. Can prevent soil particles from being washed away or eroded

5. Has good anti-aging properties and chemical corrosion resistance

Polypropylene nonwoven geotextile, referred to as PP geotextile, it is a non-woven fabric made of polypropylene fiber as the main raw material.

Material: PP

Weight:100-800g

Width: 1-7m

Length: 50-200m (customizable)

Color; white, black, orange, supports custom colors

Features:

1. Light weight and excess strength: Polypropylene geotextile has a smart looking out weight and immodrate tensile strength. They can face up to sufficient extrusion forces at some stage of the mission and are very durable.

2. Good acid and alkali resistance: Polypropylene geotextile can face up to erosion and corrosion from a range of acids, alkali, salts and chemical resources, and performs precisely in harsh soil environment.

3. Good regional neighborhood climate sealing: PP geotextile has specifically sturdy close by nearby climate sealing, can stand up to the sealing penalty of ultraviolet radiation and shut by way of capability of the use of shut thru nearby local weather changes, and can keep the integrity of the creating for every day acceptance of the material.

4. Good water permeability and air permeability: Polypropylene geotextile ground typically has a pinnacle pore shape with notable water permeability and air permeability, and can maintain soil moisture and gasoline exchange.

5. Good environmental protection: polypropylene geotextiles are made of commonly used environmentally exceptional uncooked materials. It is non-toxic, odorless, degradable and will no longer motive air pollution to the environment.

Application:

1. Water conservancy project: PP geotextile in water conservancy assignment of rivers, reservoirs, dams with seepage control, anti-slip, anti-scouring residence.

2. Foundation engineering: PP geotextile can be used for tough soil, plugging soil, consolidation, landscaping, etc., and actively create steady and dependable labor-saving projects.

3. Road project: PP geotextile can be used for toughening and stabilizing the base layer and street surface, making up for the channel of avenue cracks and settlement, and prolonging the existence time of the employer road.

4. Mine and landfill: PP geotextile can be used for day by day administration of mines and landfill reinforcement and seepage control, thru the air to complement the air air pollution of soil and groundwater.

5. Agricultural engineering: PP geotextile can be used for wind safety and warmth, soil moisturizing, soil care and different agricultural projects, to promote lush vegetation and harvest greater yields.

Specifications:

| Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-2017) | |||||||||||

| No. | Item | Specifications | Note | ||||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | |||

| 1 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | |

| 2 | Width deviation | -0.5 | |||||||||

| 3 | Standard breaking strength/(KN*m) | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 40 | Vertical and horizontal |

| 4 | Elongation at break % | 20-100 | |||||||||

| 5 | CBR bursting strength/KN | 0.6 | 1 | 1.4 | 1.8 | 2.5 | 3.2 | 4 | 5.5 | 7 | |

| 6 | Equivalent aperture | 0.07-0.2 | |||||||||

| 7 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||

| 8 | Longitudinal and transverse tear strength/KN | 0.1 | 0.15 | 0.2 | 0.25 | 0.4 | 0.5 | 0.65 | 0.8 | 1 | Vertical and horizontal |

| 9 | Acid and alkali resistance/% ≥ | 80% | |||||||||

| 10 | Antioxidant properties/% ≥ | 80% | |||||||||

| 9 | UV resistance% ≥ | 80% | |||||||||

Packaging:

Stock:

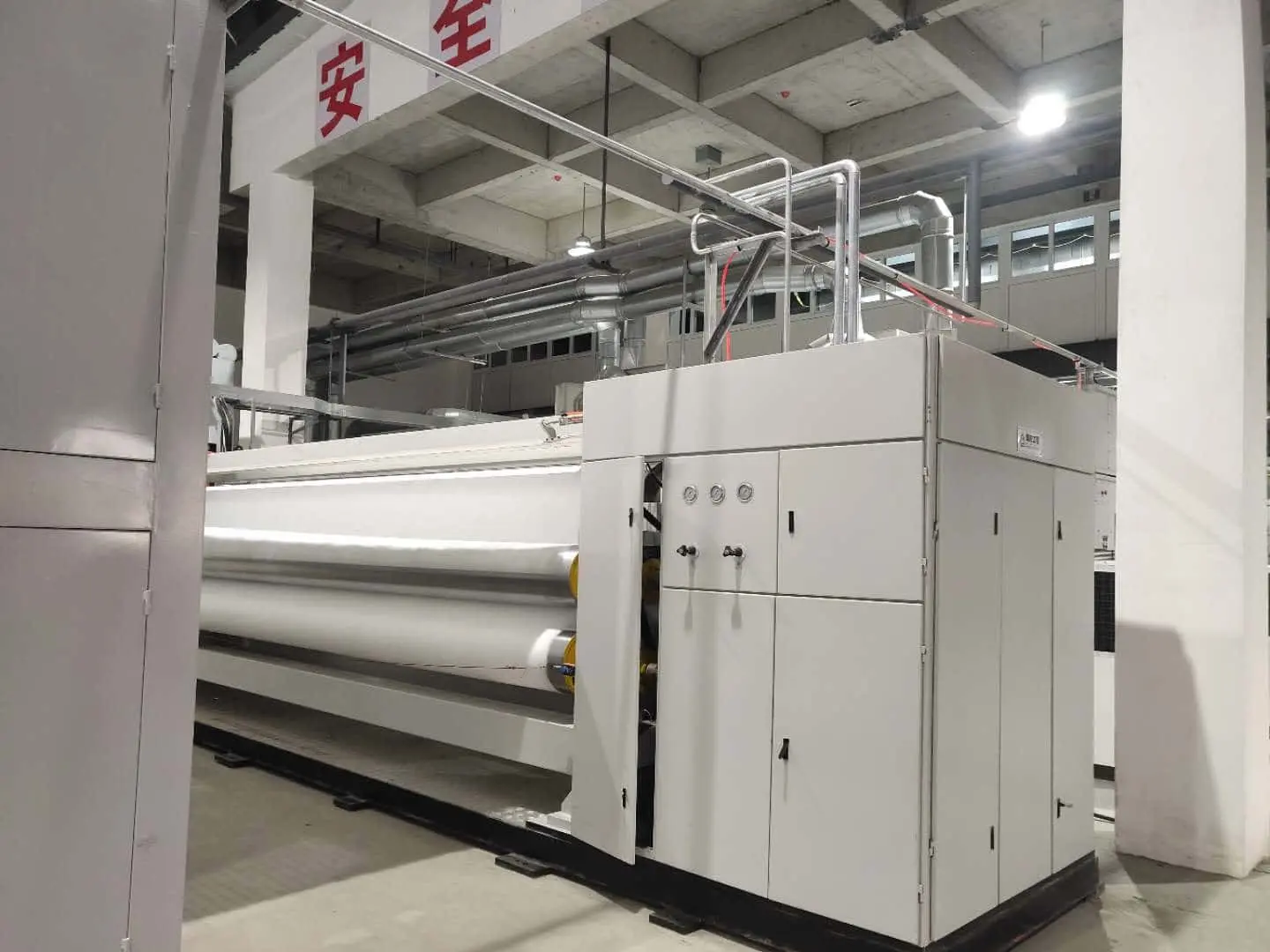

Factory: