Isolation And Reinforcement Filament Polyester Geotextile

PET geotextile is made of non-woven technology. The PET fiber is melted, sprayed, high-speed air flow and other processing processes to form a network structure, and then processed by heat setting, compaction, coating and other processes.

PET geotextile is a geotechnical material made of polyester fiber.

1. Has high tensile strength and good anti-penetration properties

2. Excellent corrosion resistance

3. Has good waterproof performance and breathability

PET geotextile is a geotechnical material made of polyester fiber.

Material: PET

Weight:100-800g

Width: 1-7m

Length: 50-200m (customizable)

Color; white, black, orange, supports custom colors

Features:

1.High strength: PET geotextile has excessive tensile energy and anti-rupture properties, and can stand up to massive hundreds and extrusion forces in projects,

retaining long-term stability.

2.Good acid and alkali resistance: PET geotextile has exquisite chemical corrosion resistance and can face up to the erosion and corrosion of quite a number

chemical components such as acids, alkali, salts, etc., and is appropriate for exceptional soil environments.

3.Good climate resistance: PET geotextile has appropriate climate resistance, can face up to ultraviolet radiation and the outcomes of local weather change,

and hold secure cloth performance.

4.Good water and air permeability: The floor of PET geotextile frequently has a different drainage gap structure, which can gain correct water and air permeability

and preserve soil moisture and fuel exchange.

5.Good environmental protection: PET geotextile is made of environmentally pleasant substances and is non-toxic, odorless and degradable, and will now not

pollute the environment.

Application:

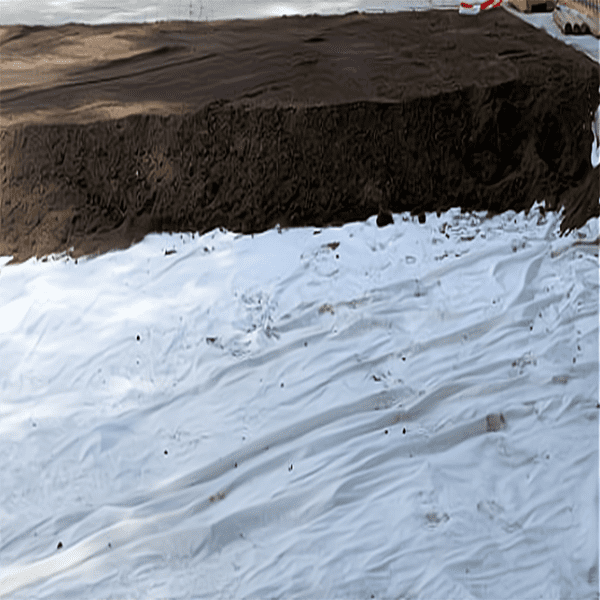

1. Water conservancy projects: PET geotextiles are appropriate for anti-seepage, landslide resistance, and erosion resistance in rivers, dams, reservoirs, etc. in water

conservancy projects.

2. Basic engineering: PET geotextile can be used for soil reinforcement, leakage prevention and soil conservation to enhance the steadiness and reliability of

primary engineering.

3. Road engineering: PET geotextiles can be used to toughen and stabilize roadbeds, decrease the incidence of avenue cracks and settlement, and prolong the

carrier existence of roads.

4. Mines and landfills: PET geotextile can be used for complete administration of mines and reinforcement and anti-infiltration of landfills to limit soil and

groundwater pollution.

5. Agricultural engineering: PET geotextile can be used in agricultural engineering such as windproof and thermal insulation, soil moisture retention and soil care to

promote crop boom and expand yield.

Specifications:

Filament Spunbonded Needled Non-woven Geotextile Technical Specifications | ||||||||||

Item | Index | |||||||||

Weight(GSM) | 100 | 150 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

Index breaking strength(KN/m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

1 | Vertical and horizontal rupture strength / (KN/ m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

2 | Vertical and horizontal standard strength corresponding to elongation % | 40-80 | ||||||||

3 | CBR bursting strength /KN | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

4 | Vertical and horizontal tearing strength /KN | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 |

5 | Equivalent aperture O90(95)>/mm | 0.05-0.20 | ||||||||

6 | Vertical permeability coefficient | K*(10-1~10-3)and K=1.0~9.9 | ||||||||

7 | Thickness / mm≥ | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

8 | Width deviation | -0.5 | ||||||||

9 | Unit area mass deviation | -5 | ||||||||

Packaging:

Stock:

Factory: