Waterproof and corrosion resistant HDPE geomembrane

HDPE geomembrane is produced by three-layer co-blowing process or calendering process. It is an effective waterproof barrier engineering material.

1. Excellent anti-penetration performance, waterproof, anti-seepage and isolation

2.High chemical corrosion resistance

3. Better impact resistance and wear resistance

Product descriptions from the supplier

Overview

Type: HDPE Geomembrane

Brand: TaiWei

Material: 100% HDPE

Warranty service: within 10 years

Country of Origin: China

Raw Materials: High-density polyethylene

Width: 1-8m

Length: 50-200m (customizable)

Thickness: 0.2-3mm

Color:black, white, supports custom colors

After-sales service: online technical support, online installation training, product standard testing, free spare parts, returns and exchanges.

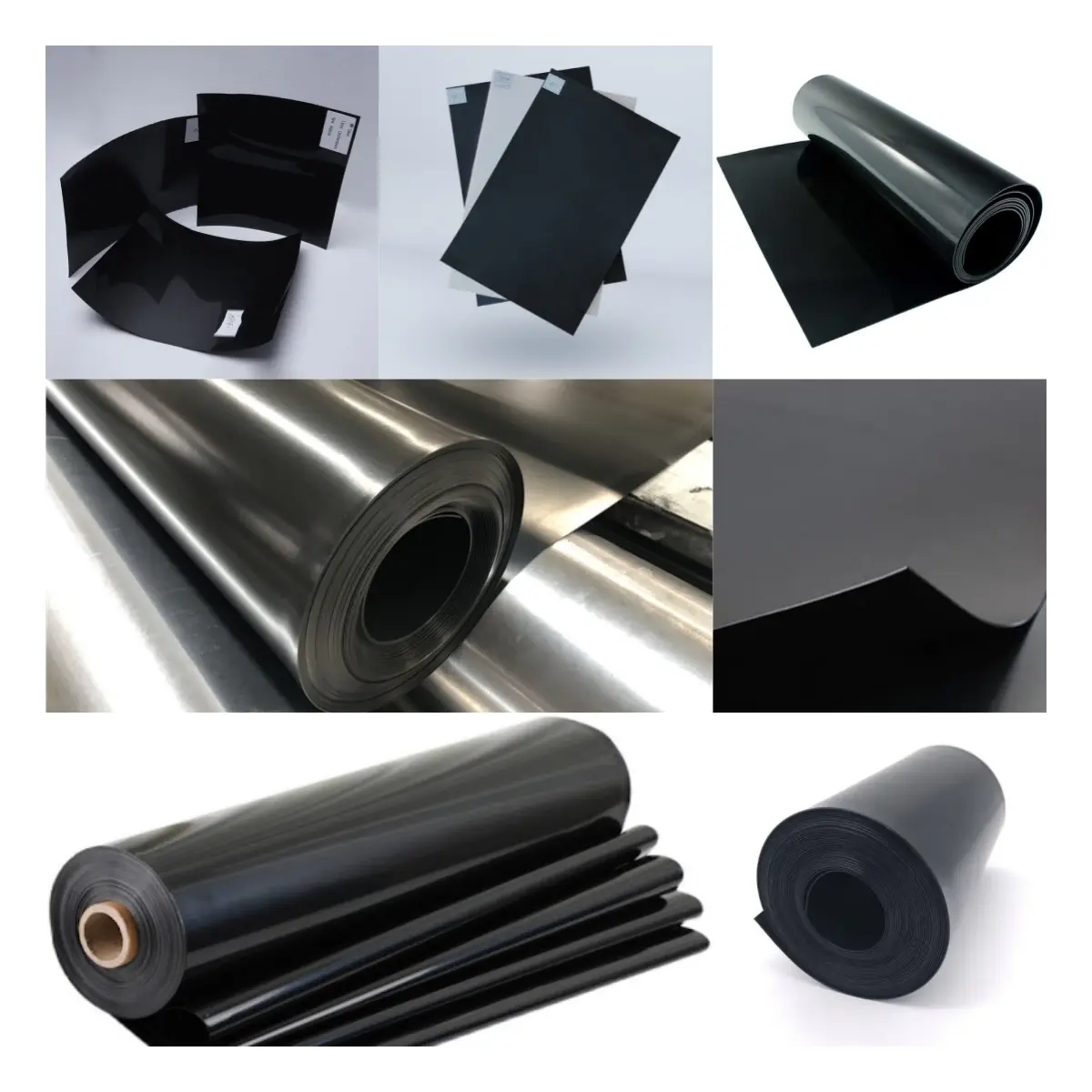

Product Display

Product Features

1. HDPE geomembrane has notable chemical stability, can stand robust acid, alkali, oil corrosion. It is a high-strength anti-corrosion material;

2. HDPE geomembrane has special brilliant tensile strength, which can meet the desires of a range of high-standard projects;

3. HDPE geomembrane has sturdy climate resistance and anti-aging properties, and can be used for a lengthy time except reducing its performance;

4. HDPE geomembrane has throughout each day performance. HDPE geomembrane has sturdy tensile electricity and elongation at break, which permits HDPE

geomembrane to be used in some harsh geological and climatic conditions. It is adaptable to uneven geological prerequisites and is resistant to pressure.

Product Application

1. Water conservancy projects: Anti-seepage lining materials used in reservoirs, channels, dams, rivers, etc.

2. Environmental protection: Used as anti-seepage layers in landfills, sewage treatment plants, chemical plants and other places to prevent harmful substances from seeping into groundwater or soil. can effectively prevent soil erosion and leakage.

3. Agriculture and fishery: used as anti-seepage layer in pools, fishing ponds, aquaculture farms, etc., which can effectively reduce water waste and improve breeding efficiency.

4. Transportation: Used as an anti-seepage layer for highways, railways, airports and other foundation projects to enhance the stability and durability of the foundation.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||||

Spec Properties | Test | GMS0.2 | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 | GMS3.0 |

Thickness | D5199 | 0.2mm | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm |

Density (≥ g/cc) | D1505 | 0.94 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.94 |

Tensile Properties | D6693 Type IV | 3 kN/m | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% | |

Tear Resistance (≥) | D 1004 | 25N | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N | 374 N |

Puncture Resistance(≥) | D 4833 | 64N | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N | 960 N |

Stress Crack Resistance (≥) | D 5397 | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |